If you’re working on a bathroom project for a customer and looking to install some plumbing, one of the first questions to ask is whether the existing set-up is fit for purpose, or whether it needs adjusting. For example, if you’re moving the location of any taps, there will almost certainly be some pipework that needs doing.

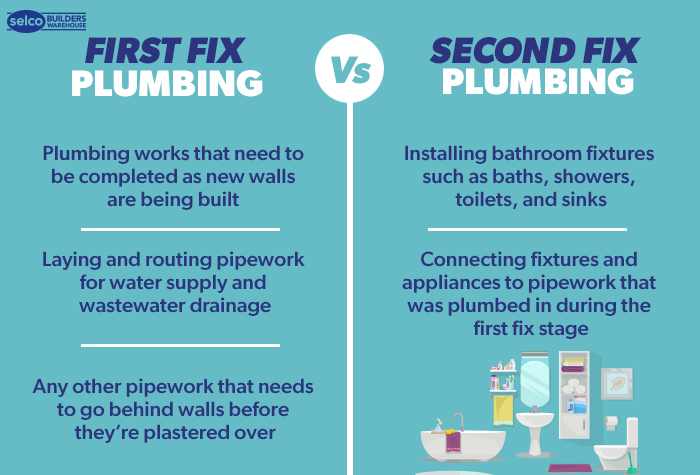

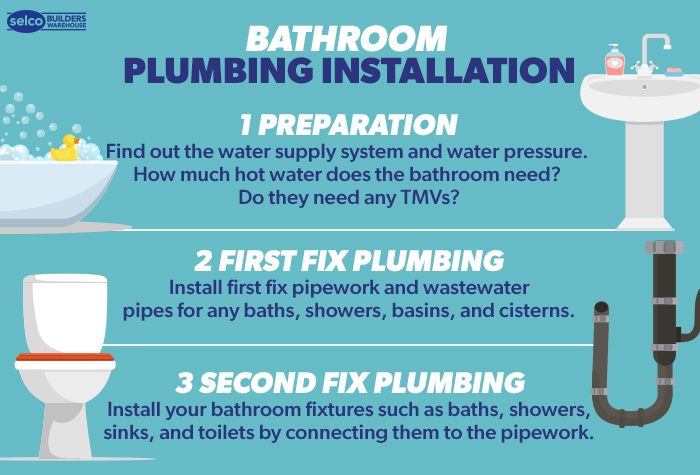

Here we’ve put together a helpful guide on how to plumb a bathroom properly, including steps for first fix and second fix plumbing. First fix plumbing happens first in the new build process, where all the routing and laying of the pipework occurs to build a strong foundation. Then, in second fix plumbing, the appliances and fixtures are connected to the pipework.

Firstly, make sure you have the right plumbing supplies to hand before getting started on your bathroom project. You’ll want to have a nice selection of plumbing tools, such as pipe cutters, pipe cleaners, wrenches and spanners, as well as wastes and pipework and other plumbing and heating supplies.

As well as your bathroom plumbing fittings, you’ll need your bathroom fixtures and accessories to get the job done – have a browse through our Selco bathroom brochure to get some inspiration.

Remember to browse our other blogs for more specific step-by-step guides to installing bathroom fixtures, such as our handy blog on how to fit a toilet.

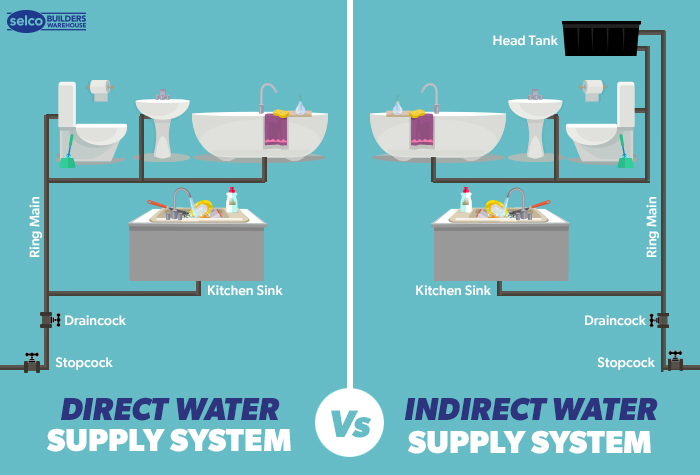

What’s the difference between a direct or indirect water supply system?

Your customer’s home will either be fitted with a direct system or an indirect water supply system. This is to do with how cold water travels through the pipework and around the home. Each system has its own benefits and advantages depending on the property.

Indirect water supply system

In an indirect system, it only sends cold water to the kitchen tap. Other cold water flows into a cistern or water tank that usually sits in a loft or airing cupboard. This cistern then stores the water and supplies it to the rest of the house, such as cold bathroom taps and a hot water cylinder.

Direct water supply system

In a direct system, the cold taps are drawn from the mains supply. This sends cold water to every point in the home that needs it, at mains water pressure. If there’s a cold-water cistern, it will only provide water for your hot water cylinder.

It’s important to know the difference between these systems because you’ll need to establish what the hot water system is before your customer can pick out taps and showers.

High-pressure water system

Some taps and shower valves rely on high-pressure systems to work properly. High-pressure water systems are more common in newer and smaller homes, and they provide hot water on demand using a combi boiler. When the hot tap is turned on, the boiler senses the flow of water, activates the heat exchange unit and heats the water as it passes through. The flow must be at a certain pressure for the water to be heated.

It’s important to ask what kind of water pressure your customer currently gets from their system when considering shower flow rate. If they’ve got their heart set on a power shower with a water flow rate of 30ltrs per minute at 3-bar pressure, but their system only delivers 15ltrs at 1 bar, they’re going to be disappointed! Now, let’s look at the bathroom plumbing system basics:

A step-by-step guide to first & second fix bathroom plumbing

Step 1: How much hot water does your customer need?

Extra bathrooms are more popular in modern houses. You’ll often find a downstairs toilet or cloakroom, an upstairs family bathroom, plus one or more en-suite bathrooms. Your client may want to fit extra bathrooms or en-suites into their home, especially if they’ve got a larger family or regular guests. The question is, do they have enough water to supply each bathroom? No-one wants the hot water running out after just a couple of showers in the morning.

Do the water flow maths:The average shower produces around 9ltrs of water every minute, so for a 5-minute shower you’ll need 45ltrs of water. If your customer fancies installing a power shower, or they have family members that enjoy longer showers, they might be in trouble!

A typical water tank – the kind that sits in the airing cupboard – will hold between 110 – 250ltrs of water. If it’s an extra bathroom you’re installing, the tank will need to be at the top end. If it isn’t, you might have to manage your customer’s expectations as to what is realistic.

Step 2. Bathroom water temperature

There are some strict guidelines that cover hot water temperature in the home. Water needs to be stored above 60°C to prevent bacteria forming, but you certainly wouldn’t want it coming out of a shower at that temperature. A lot of modern showers are fitted with thermo-static mixer valves (TMV) to keep the temperature down. But you’ll need to consider each customer’s needs separately – if they like to take long, relaxing baths, topping it up with hot water every so often, then you might not want to fit a TMV on the bath taps.

Step 3. First fix plumbing

The first fix process of building a home involves the initial installation of stud walls and framing, plumbing and electrics. First fix plumbing involves all the plumbing works that need to be completed as new walls are being built, such as laying/routing pipework. A lot of plumbing installation would be extremely difficult to do after the house has been built.

First fix plumbing will take place at the same time other projects like first fix electrics, so make sure your schedules are staggered to prevent different trades getting in each other’s way during this initial installation stage.

Step 3.A. First fix pipework

First fix pipework plumbing might include:

- Pipework for the house’s water supply, including underground pipework

- Pipework for the drainage of wastewater

- Pipework for the boiler or hot water cylinder

- Any other pipework that needs to go behind walls before they’re plastered over

You’ll most likely be working with 15-22mm plastic or copper pipes. To save time, you might want to consider using push-fit pipes in your bathroom plumbing, from brands such as JG Speedfit and Polyplumb. As the name suggests, push-fit piping fits together quickly and easily with a simple push, which is much faster than soldering copper pipes together. Whatever pipework you’re working with, the supply pipes for both the shower and bath taps should be laid under the floorboards so they’re easy to access if needed.

Step 3.B. First fix pipework installation tips

Here are a few pointers you need to consider for each different piece of bathroom furniture. Remember you need to get the shower and bath installed during the first fix, and that you’ll need to make sure it’s properly waterproofed before everything is tiled over.

Bath plumbingWhen it comes to baths, you’ll need to install a shallow waste bath trap (1.5”) as well as a 1.25” basin waste. Any existing washers might still be in decent condition, but it’s always advisable to swap old washers for new ones.

Shower plumbingIt’s sensible to fit a flow limiter valve before installing showers. If there’s an imbalance between the cold and hot water pressure at the point it arrives at the shower mixer, your customer could end up with poor water temperature, or a backing up of water through the valve.

BasinsIf the current basin waste pipe is directly in line with the waste outlet in the basin, you’ll need a pedestal or bottle waste, the outlet of which is immediately below the inlet.

CisternsThe only thing to bear in mind with the cistern at this stage is whether or not it has a side entry water inlet. If so, you won’t be able to use a flexible tap connector – you'll need to use a copper one.

Step 3.C. First fix wastewater

Ensuring good waste disposal is probably the most important job during the first fix of pipework. Different types of bathroom suites will require different tasks at this point – you might need to connect waste pipes from the toilet, shower, bath and basin to allow waste and soil water to drain efficiently away into the soil vent pipe. Remember to use the correct diameter pipe for each job, or you might need to come back to unblock something later.

In accordance with the latest building regulations for waste pipe falls, you need to fit the toilet as close as possible to the soil vent pipe. You’ll need to locate the 100m diameter soil vent pipe as this will have a big impact on where you can locate the toilet within the bathroom.

Above-ground drainage systems are straightforward to install, especially if you have push-fit fittings. Of course, it is worth remembering that solvent-weld pipework is the most durable. If you’re going to conceal the pipework or if it’ll be inaccessible once the job is done, solvent-weld might be the way to go.

Step 4. Plumbing behind the wall

If your customer’s going for a ‘hotel-style’ bathroom they might ask you about wall-hung or back-to-wall plumbing. This involves ‘floating’ toilets and sinks that seem like they’re floating on the wall rather than being attached to the floor. As you’d expect, anything hung like this will require a cistern that’s attached to a wall-hung frame and plumbed in behind the wall. The frames are usually adjustable, or have adjustable feet, so you can raise and lower the height. You can mount them on frames on the drywall, then tweak the height to the right specs.

Step 5. Second fix plumbing

As you might have figured out, second fix plumbing takes place after the build is finished and all the internal walls and floors are complete. This is the stage where you’ll connect all the plumbing you put in during the first fix stage and install a variety of bathroom fixtures and fittings.

All the plumbing and electrical foundations for your bathroom appliances will be laid out for you, and you’ll just need to connect everything to the pipework. Some jobs you’ll need to carry out at the second fix plumbing stage include:

- Installing a basin or sink

- Installing a bath

- Installing a shower

- Connecting radiators and boilers to pipes laid down during first fix plumbing

Get the supplies you need

FAQs

-

What are the main bathroom pipework installation points?

In the first fix bathroom plumbing stage, you might need to install shallow waste bath traps and basin waste, as well as new waste outlets for the sink and potentially a flow limiter valve for the shower.

-

How much hot water does the bathroom need?

On average, a typical 5-minute shower will need 45ltrs of water, so from this you can estimate how much hot water your customer is likely to get through.

-

How will the water system affect my plumbing?

Whatever taps, shower valves and other bathroom fixtures and fittings you decide on will be affected by whether your customer has a direct or indirect plumbing system. Also, whether they have a low-pressure or high-pressure water system might limit their shower options too – with a low-pressure system, they might not be able to install a power shower with a strong flow.

-

When do I fit the flooring in a bath installation?

If you’re working with a freestanding bath, lay the bathroom tiles underneath first, but if your bathtub is closed in, you won’t need to tile that area.

-

How do I install a bathtub?

The 6 key steps are:

- Assemble the bathtub’s legs or frame

- Add in any other separate parts

- Position the bathtub where it will be installed

- Connect the plumbing and pipework to the bath

- Secure the bath to the floor

- Attach any bath panel

-

Should I fit a shower before the bath?

If the bathtub is going to have a shower over it, then the bath does need to be fitted and plumbed first.

-

How do I remove the bath?

When it comes to the bath, make sure to disconnect any waterpipes feeding the tap and if the bath isn’t freestanding, remove the panel hiding the plumbing.

-

How do I remove the basin?

Make sure both the water and electricity are turned off. Have a colleague support the basin as you unscrew the fittings. You can use a suitable knife to cut away any silicone sealant or grouting. Then you can dispose of the basin. To remove the pedestal, remove the sealant under the basin and at the bottom of the stand on the floor. Lift the basin up, slide the pedestal out, then put the sink back onto the wall bracket. You can read our helpful guide for tips on bathroom removal and making room for a new suite or fixtures.

By Rae Davis

Rae is a Digital Copywriter within the Selco Team with 10 years' experience in the construction industry and specialises in long-form content writing. With a love for research and simplifying complicated information into easy-to-follow content, she is known for her handy how-to blogs. When she’s not at her desk, she’s got her head either in a book or up in the clouds.

< Back to Plumbing